Alternating copolymerization Battery Block polymer Bottlebrush polymer CCS polymer Composite Copolymer Cross-linking Emulsion Graft copolymer Hierarchical pore structure Hyper-cross-linking Interface Ionic liquid Macroporous Membrane Mesoporous Metal nanoparticle Micelles Microfluidics Microphase separation Microporous Mixed-matrix membrane MOF Noncovalent interaction Permselectivity Phase separation Phase transition Photopolymerization PIMS PISA Poly(arylene ether) Polycondensation Polymer particle Porous polymer Postpolymerization modification RAFT polymerization ROP Self-assembly Sequence control SNAr reaction Sulfonation Supramolecular chirality Surface modification Thiol-ene reaction

Hierarchically porous polymers containing multiscale pores are attractive for applications where rapid mass transport to the large pore surface is important. By combining pores of more than one length scale in the pore structure, substances can readily diffuse into the porous space provided by the larger pores and rapidly access to large surface generated by the smaller pores. To realize this possibility, it is important to construct hierarchical pore structure where pores with different length scales are mutually interconnected. Also, pore size at each length scale should be orthogonally controlled to achieve pore size-dependent properties such as size-selective adsorption.

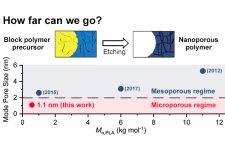

According to IUPAC recommendation, pores are categorized into micropores (< 2 nm), mesopores (2 – 50 nm), and macropores (> 50 nm). Based on the polymerization-induced microphase separation (PIMS) process which is highly suitable for the synthesis of well-defined and robust mesoporous polymers with three-dimensionally continuous pore structure,1 we are working on developing hierarchically porous polymers containing more than mesopores so we can simultaneously achieve large surface area (= large sorption capacity) with facilitated diffusion (= enhanced kinetics).

Hierarchically porous polymers containing micro- and mesopores

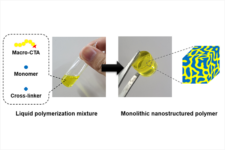

In principle, the PIMS process can be applied to any homogeneous polymerization mixture containing a macro-chain transfer agent, a monomer, and a cross-linker where the constituting blocks in the emergent block polymer are not compatible to each other, such as polylactide macro-chain transfer agent (PLA-CTA), styrene (S), and divinylbenzene (DVB).

We utilize vinylbenzyl chloride (VBzCl) in the PIMS process by combining with PLA-CTA and DVB to create a hierarchically porous polymer containing micro- and mesopores. VBzCl is a well-known styrenic monomer used for synthesis of microporous polymers via hyper-cross-linking. Typically, P(VBzCl-co-DVB) resin is reacted with Lewis acid such as FeCl3 to promote Friedel-Crafts alkylation between aromatic rings and form methylene bridges in the swollen state. Free volume between the polymer chains is arrested as a result of the reaction and converted into permanent micropores of ~ 1 nm.

We synthesize PLA-b-P(VBzCl-co-DVB) precursors by copolymerization of VBzCl and DVB in the presence of PLA-CTA via reversible addition-fragmentation chain transfer (RAFT) polymerization mechanism. The resulting precursor consisting of bicontinuous PLA and P(VBzCl-co-DVB) microdomains is reacted with FeCl3 in 1,2-dichlorethane to create micropores in the P(VBzCl-co-DVB) framework. Simultaneously, FeCl3 also degrades PLA by attacking C-O linkage in the PLA backbone resulting in formation of mesopores.

The resulting hierarchically porous polymer exhibits high surface area (> 1000 m2 g-1) originated from the micropores, and facilitates diffusion of substances through the 3D continuous mesopores.2 We also note that the hyper-cross-linking reinforces the mesoporous framework by knitting the aromatic groups, providing higher chemical and thermal stabilities.3

Hierarchically porous polymers containing micro-, meso-, and macropores

We have also developed hierarchically porous polymers containing micro-, meso-, and macropores by combining three different length scales of pores across nanometer to micrometer within one material. Inspired by the success of operating the PIMS process in water/oil/water double emulsion drops,4 high internal phase emulsions (HIPE) are used as a template for the macropore structure in the hierarchically porous polymer synthesis. HIPE contains micrometer-sized aqueous droplets dispersed in a continuous oil phase, and volume fraction of the aqueous phase is > A macroporous polymer with interconnected macroporous voids, polyHIPE, can be readily produced by using S/DVB mixture as the oil phase, conducting radical polymerization, and removing the aqueous phase.

The PLA-CTA/S/DVB mixture can be used as the oil phase to produce a polyHIPE, where the framework contains bicontinuous PLA and cross-linked P(S-co-DVB) microdomains as a result of the PIMS process. Subsequent PLA etching results in a hierarchically porous polyHIPE (h-polyHIPE) containing mesopores within the macroporous framework. Further reacting the polymer with an external cross-linker for hyper-cross-linking creates micropores within the P(S-co-DVB) framework, and yields the desired hierarchically porous polymer, h2-polyHIPE.5

Because the pore forming methods for the different length scales in h2-polyHIPE are orthogonal to each other, it is possible to control mesopore size in a wide range by adopting the additive methodology.6 Dye adsorption kinetics of h2-polyHIPE indeed suggests that the hierarchical pore structure is critical in facilitating diffusion of the substances, and the multiscale pore structure in h2-polyHIPE is mutually interconnected.

1. “Reticulated nanoporous polymers by controlled polymerization-induced microphase separation”, Myungeun Seo and Marc A. Hillmyer*, Science 336, 1422–1425 (2012).

2. “Hierarchically porous polymers from hyper-cross-linked block polymer precursors”, Myungeun Seo*, Soobin Kim, Jaehoon Oh, Sun-Jung Kim and Marc A. Hillmyer, J. Am. Chem. Soc. 137, 600-603 (2015).

3. “Control of porosity in hierarchically porous polymers derived from hyper-crosslinked block polymer precursors”, Soobin Kim and Myungeun Seo*, J. Polym. Sci. Part A: Polym. Chem. 56, 900-913 (2018) (selected as a Front Cover).

4. “Semipermeable microcapsules with a block polymer-templated nanoporous membrane”, Jaehoon Oh, Bomi Kim, Sangmin Lee, Shin-Hyun Kim*, and Myungeun Seo*, Chem. Mater. 30, 273-279 (2018).

5. “Hyper-cross-linked polymer with controlled multiscale porosity via polymerization-induced microphase separation within high internal phase emulsion”, Jongmin Park, KyuHan Kim, and Myungeun Seo*, Chem. Commun. 54, 7908-7911 (2018).

6. “Effect of homopolymer in polymerization-induced microphase separation process”, Jongmin Park, Stacey A. Saba, Marc A. Hillmyer*, Dong-Chang Kang, and Myungeun Seo*, Polymer 126, 338-351 (2017) (Invited Paper to a Special Issue “Porous Polymers”).