Marine biofouling is a significant problem that occurs when aquatic organisms like algae, barnacles, and diatoms cling to submerged surfaces such as ship hulls, docks, and buoys. This unwanted accumulation not only creates additional drag, which increases fuel consumption for vessels, but also contributes to higher greenhouse gas emissions, making it a pressing environmental issue.

Traditionally, hydrophilic coatings have been used to create a slippery barrier against these marine organisms. These coatings attract water, forming a hydration layer that helps keep surfaces clean in sediment-free conditions. However, this effectiveness is quickly compromised in environments rich in sediment. Here, sediment particles prefer to adhere to the same hydrophilic surfaces, leading to a significant loss in the antifouling properties of these coatings.

To tackle this challenge, researchers are exploring a new class of materials: amphiphilic copolymers. These novel coatings are designed to repel both diatoms and sediment, potentially providing a solution to biofouling in real-world scenarios, where sediment is often present. Initial investigations indicated that achieving the right balance between hydrophilic and hydrophobic properties is crucial for effective antifouling.

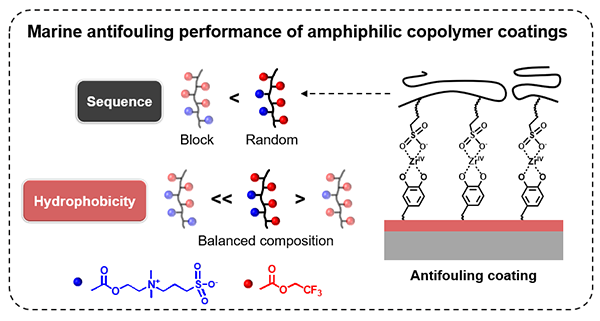

One of the obstacles researchers face is the variation in the structure of these copolymers, which often results from in situ polymerization processes that are not well defined. A fundamental question remains: Would a block arrangement or a random sequence of the polymer building blocks work better for antifouling purposes? Surprisingly, this essential aspect had not been thoroughly examined—especially the impact of sediment on diatom adhesion.

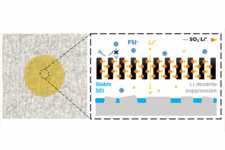

We tackled this challenge by combining a technique known as polydopamine precoating with precisely engineered amphiphilic copolymers made through a controlled polymerization method. We collaborated with Professor Sung Min Kang and Jinhyeok Jeong at Chungbuk National University, who developed the developed a robust, simple, and scalable coating process using zirconium (Zr(IV))-mediated coordination bonds to create thick and durable copolymer coatings on commonly used substrates like stainless steel.

In our group, Minjoong Shin employed reversible addition-fragmentation chain transfer (RAFT) polymerization to synthesize amphiphilic copolymers composed of zwitterionic sulfobetaine methacrylate (SBMA) for hydrophilicity and hydrophobic trifluoroethyl methacrylate (TFEMA) with control over the TFEMA/SBMA ratios, sequence, and molecular weights of the copolymers. Remarkably, these coatings remained stable in seawater for several weeks without significant degradation. Upon testing the new coatings against diatoms, incorporating silt for the first time, we found that a random copolymer with an optimal balance of hydrophilic and hydrophobic elements outperformed its diblock copolymer counterpart, which performed poorly.

These findings suggest that effective antifouling requires a strategic arrangement of both hydrophilic and hydrophobic groups on the surface, promoting a synergistic effect that simultaneously combats both diatom adhesion and sediment accumulation. Impressively, the random copolymer coating showcased superior antifouling performance compared to other zwitterion-containing coatings previously reported, both in terms of effectiveness and longevity. This innovative approach to antifouling coatings could revolutionize marine technology, providing solutions to enhance the efficiency and sustainability of marine vessels while protecting our oceans from the impacts of biofouling.

The whole story can be found in an open-access article published in NPG Asia Materials:

Jeong, J., Shin, M., Kang, S.M., Seo, M. Sediment-resistant marine antifouling amphiphilic random copolymer coating. NPG Asia Mater 17, 24 (2025). https://doi.org/10.1038/s41427-025-00606-7