Nanoporous materials have promising applications such as filtration, separation, storage, and catalysis. Block polymer self-assembly provides a powerful route to well-defined nanoporous polymers with extraordinary control over pore size, structure, and functionality. We are exploring synthesis of block polymer-based nanoporous polymers and control of transport through nanopores by size for energy and catalytic applications.

1. Polymerization-induced microphase separation (PIMS)

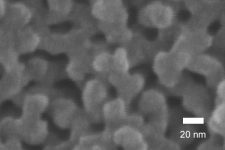

PIMS is a spontaneous microphase separation process driven by formation of block polymers in situ in the polymerization mixture. Typically, copolymerization of a monomer and a cross-linker in the presence of a macro-chain transfer agent (macro-CTA) is performed in bulk (i.e., no solvent). The most well-studied system is styrene (S)/divinylbenzene (DVB)/polylactide (PLA)-CTA. In this case, the reversible addition-fragmentation chain transfer (RAFT) copolymerization grows P(S-co-DVB) copolymer off from the end of PLA-CTA to form PLA-b-P(S-co-DVB) block polymer. Because DVB contains two double bonds, the forming block polymer is simultaneously being cross-linked. At a critical conversion, the whole polymerization mixture becomes gelled due to formation of the P(S-co-DVB) network. Also, the increased molar mass of P(S-co-DVB) and consumption of S and DVB monomers (which can be considered as solvents too) drive the system to microphase-separate and order. When the DVB molar fraction is high enough, a disordered bicontinuous structure composed of PLA and P(S-co-DVB) microdomains is arrested by the in situ cross-linking. A densely cross-linked and microphase-separated block polymer can be obtained in a nearly quantitative yield after completion of the polymerization, which eliminates needs for any postpolymerization steps (workup, processing, aligning, cross-linking, …). By simply immersing the polymer in a basic solution, PLA as a sacrificial block can be readily etched out to produce a robust nanoporous polymer composed of P(S-co-DVB) framework and three-dimensionally (3D) continuous pore structure.

As a block polymer self-assembly process, the PIMS process provides precise control of pore size by adjusting molar mass of the sacrificial block. Moreover, the PIMS process offers several important advantages over conventional block polymer self-assembly processes particularly for synthesis of porous polymers. First, 3D continuous pore structure allows facile transport of substances without a hassle of aligning the microphase-separated structures. While a gyroid phase is well-known in the block polymer literature for its bicontinuous morphology which can be utilized for the synthesis of 3D porous polymers, narrow window of the gyroid phase causes synthetic difficulties and limits control of porosity. In the PIMS process, the bicontinuous structure is spontaneously obtained as a result of polymerization and porosity can be controlled by the weight fraction of PLA-CTA in the polymerization mixture. Second, the densely cross-linked framework generated by in situ cross-linking provides mechanical and thermal stability to the porous polymer. Third, it is possible to access pores smaller than 10 nm. In the block polymer self-assembly, forming microphase-separated structures with smaller feature size has been challenging due to thermodynamic restrictions. Deriving porous polymers from such precursors has been another challenge as small pores are prone to collapse under Large Laplace pressure inflicted by the large surface area. By arresting of the microphase separation process via in situ cross-linking, reduction of pore size down to 4 nm (by BJH analysis of the nitrogen sorption isotherm) has been reported by utilizing the PIMS process.

Since the first report in Science by Seo and Hillmyer at the University of Minnesota in 2012 (“Reticulated nanoporous polymers by controlled polymerization-induced microphase separation”, Myungeun Seo and Marc A. Hillmyer*, Science 336, 1422 (2012)), the PIMS process has been widely investigated not only for synthesis of porous polymers but also for fabrication of bicontinuous nanostructures for energy applications. Here key achievements reported by the Seo group for synthesis of porous polymers are summarized below.

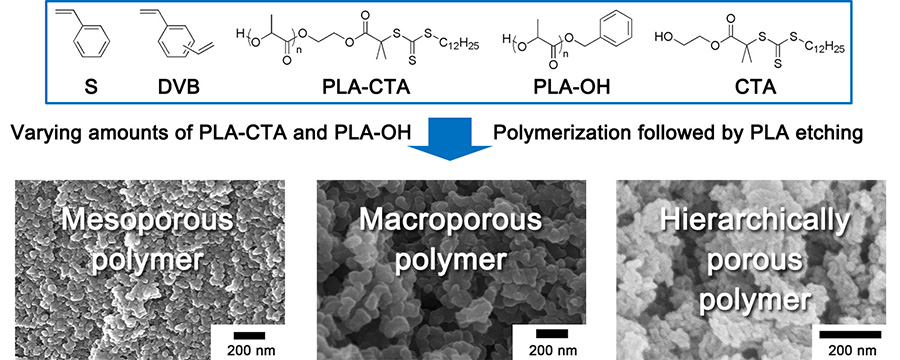

2. Additive in PIMS

Ironically, it has been difficult to increase pore size in the PIMS process while retaining the beneficial 3D pore structure because of difficulties associated with synthesizing high molar mass PLA-CTAs and making a solution of such PLA-CTAs in S/DVB. In collaboration with the Hillmyer group at the University of Minnesota and the Chae-Ho Shin group at Chungbuk National University, we have shown that adding PLA homopolymer in the polymerization mixture for the PIMS process allows straightforward control of pore size from nanometer to micrometer length scale. By adjusting molar mass of the PLA homopolymer relative to PLA-CTA, weight ratio of PLA homopolymer to PLA-CTA, and presence of molecular CTA, we were able to control the phase separation process from microphase separation of block polymer (i.e., PIMS) to block polymer-compatibilized macrophase separation (polymerization-induced phase separation, PIPS) and macrophase separation in the eary stage to yield mesoporous polymer (2 < pore size < 50 nm), macroporous polymer (pore size > 50 nm), and hierarchically porous polymer containing meso- and macropores. Read the full story published in the following article: “Effect of homopolymer in polymerization-induced microphase separation process”, Jongmin Park, Stacey A. Saba, Marc A. Hillmyer*, Dong-Chang Kang, and Myungeun Seo*, Polymer 126, 338-351 (2017).

3. PhotoPIMS

One of the drawbacks in the PIMS process is that film fabrication is relatively difficult because casting the polymerization mixture and heating may induce significant evaporation of the monomers. We have developed a route to utilizing PIMS process in the fabrication of mesoporous polymer films based on photoinitiated RAFT polymerization. Radical polymerization of acrylates and methacrylates in the presence of a photoradical initiator can proceed very rapidly at ambient temperature under irradiation of light. We have demonstrated that photoinitiated RAFT polymerization of isobornyl acrylate (IBA) in the presence of PLA-CTA and 2,2-dimethoxy-2-phenylacetophenone (DPMA) as a radical initiator can produce PLA-b-PIBA within minutes of UV irradiation at RT. Using isobornyl acrylate and ethylene glycol diacrylate as a monomer and a cross-linker in the photoPIMS process, a free-standing film could be readily fabricated and converted into a mesoporous and cross-linked polymer film. The result was published in ACS Macro Letters in 2015: “Photoinitiated polymerization-induced microphase separation for the preparation of nanoporous polymer films”, Jaehoon Oh and Myungeun Seo*, ACS Macro Lett. 4, 1244-1248 (2015).

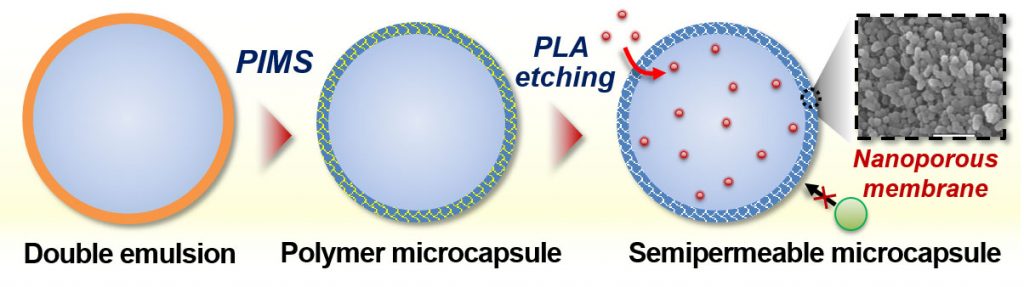

4. PIMS within W/O/W double emulsions

The PIMS process can be combined with other nanostructuring methods such as emulsification to create more complex structures. In collaboration with the Shin-Hyun Kim group at KAIST, we have demonstrated that semipermeable microcapsules with controlled pore size can be derived by PIMS of water/oil/water (W/O/W) double emulsion drops in the oil phase and subsequent PLA etching. Introducing well-defined mesopores in the shell of microcapsules are attractive for encapsulating active substances such as enzymes and quantum dots inside of the microcapsules and feeding ingredients and analytes through the mesopores. However, it is very challenging to manipulate block polymer self-assembly in the thin shell of W/O/W double emulsion drops so a robust bicontinuous nanostructure emerges and stands against collapse. The PIMS process is highly suitable in such a situation because a liquid solution is spontaneously converted into a densely cross-linked polymer monolith consisting of the desired bicontinuous microdomains. By using microcapsules with different pore size, we have shown that molecular weight cutoff of the microcapsules can be controlled by molar mass of PLA-CTA, and transmembrane diffusion can be regulated. We have published the result in Chemistry of Materials in 2018: “Semipermeable microcapsules with a block polymer-templated nanoporous membrane”, Jaehoon Oh, Bomi Kim, Sangmin Lee, Shin-Hyun Kim*, and Myungeun Seo*, Chem. Mater. 30, 273-279 (2018).